- Membership

- NAFEMS World Congress 2025

- Training

- Events

- Community

- Resources

- Resource Centre

- aiolas | AI-Powered Direct Question Search

- EMAS - The NAFEMS Journal

- International Journal of CFD Case Studies

- BENCHMARK Magazine

- NAFEMS Glossary

- E-Library

- German Magazin

- Publications

- Invitation to Tender

- Analysis Agenda

- NAFEMS Standards Initiative

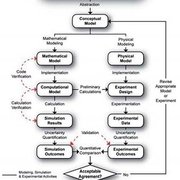

- Code Verification

- Knowledge Base

- The NAFEMS Benchmarks

- International Journal of CFD Case Studies

- Blog

- Professional Development

- Services

- About Us