MESMco19 | Explain how the interaction of stress concentrations may be handled. |

MASco5 | Discuss the general issue of scatter in material properties relevant to your analysis and simulation and how this is allowed for. |

MASco8 | Explain, in metallurgical terms, how fatigue cracks form and grow in metallic materials. |

MASco9 | Explain, in metallurgical terms, how brittle and ductile cracks form in steels and how their appearances differ. |

MASkn4 | List any material temperature limits (high and low) specified for the materials commonly used in your industry sector. |

FATkn3 | List potential sites for fatigue in your company products. |

FATkn4 | Sketch a sinusoidal stress variation and show the maximum stress, minimum stress, mean stress, alternating stress (or stress amplitude), stress range and stress ratio. |

FATkn6 | List ways of inducing beneficial compressive stresses in your company products. |

FATco1 | Discuss the initiation, propagation and fast fracture stages of Fatigue in metallic materials. |

FATco2 | Describe how the data used to construct an S-N curve are obtained. |

FATco3 | Discuss the term high cycle fatigue, highlighting a common source in your company products. |

FATco4 | Discuss the statistical nature of fatigue and explain how this is handled in relevant design standards and codes of practice. |

FATco5 | Discuss the salient features of an S-N diagram for steels and explain the terms endurance limit, infinite life and low cycle fatigue. |

FATco7 | Discuss the observed relationship between endurance limit and static tensile strength for steels and explain why this relationship does not hold for welded steels. |

FATco11 | Explain the use of Endurance Limit Modifying Factors in Stress-Life based fatigue assessment. |

FATco12 | Discuss how temperature, plate thickness and modulus effects are typically handled in relevant design standards and codes of practice and explain why this is necessary. |

FATco14 | Discuss the term Fatigue Strength Reduction Factor in relation to stress concentrations and explain how this has traditionally been handled in relevant design standards and codes of practice. |

FATco15 | Discuss the concept of cumulative damage and explain how this is commonly handled. |

FATco16 | Explain why a multiaxial stress field can complicate an analysis and discuss approaches to handling this. |

FATco17 | Discuss the significance of the choice of equivalent stress used in the fatigue assessment of welded joints |

FATco18 | Outline a conservative approach to situations where the directions of principal stresses vary during a stress cycle. |

FATco25 | Reflect on why fatigue is such a long-standing and persistent cause of failure. |

FATco35 | Discuss the term endurance limit for many non-ferrous metals, steels in a corrosive environment and the possible effects of load sequencing. |

FATco36 | Discuss any particular characteristic fatigue properties and behaviour for any materials being considered in analyses and assessment. |

FATco37 | Reflect on how variable amplitude load sequencing can affect the prediction of damage accumulation and fatigue life. |

FATap2 | Carry out elastic fatigue assessment using design standards and code guidelines for components and structures including any special procedures for ancillary components such as bolts, |

FATap3 | Modify the results of an elastic analysis for the effects of plasticity, where necessary. |

FATap5 | Use Reservoir Counting / Rainflow Method or similar to specify the necessary stress ranges, number of cycles and loading history for any component to be analysed. |

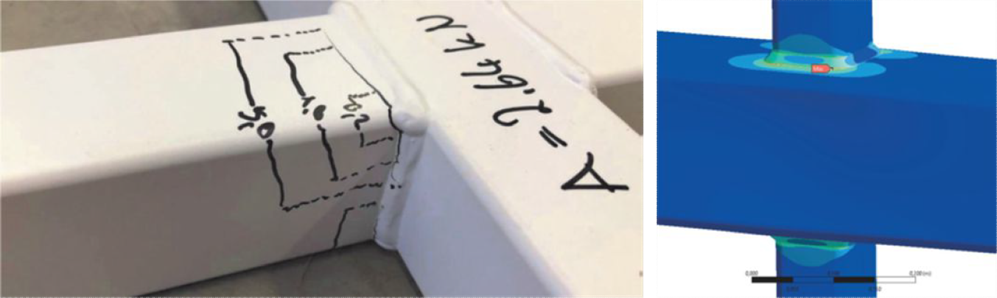

FATap6 | Employ a finite element analysis system for the fatigue analysis of a component or structure. |

PLASap2 | Use FEA to determine Limit Loads for a range of components. |

PLASap7 | Using standard material data, derive a true stress vs true strain curve to be used for nonlinear analysis. |

PLASco21 | Explain the rationale behind the 5% strain limit in some codes of practice. |